Industry

Manufacturing and production

In a nutshell

All businesses need protection against cyber attack. Manufacturing and production SMEs are embracing digital transformation, from smart sensors and cloud platforms to AI-driven analytics and remote diagnostics. With this transformation comes a growing cyber risk that threatens not just business data, but operational systems, physical safety, uptime, and reputation.

CyberSolver was created to help SMEs cut through the noise. Our six tailored solutions are designed to get businesses focused on what really matters, whether you're just starting out or need strategic board-level support. What do we offer specifically for SMEs in the manufacturing, production and other IT-connected industries?

The Expanding Attack Surface

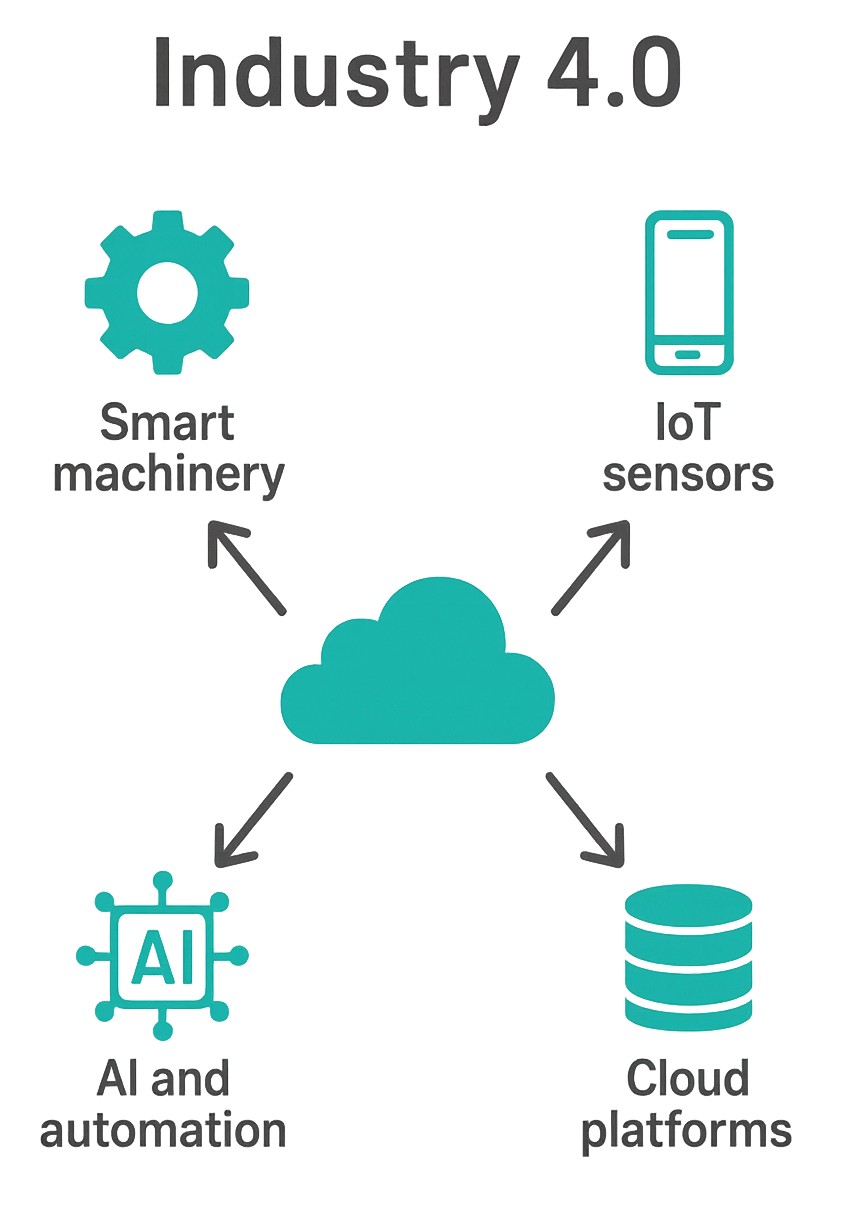

Industry 4.0 introduces a web of interconnected systems including sensors (IoT), cloud platforms, AI engines, and legacy Operational Technology (OT) devices. Each new connection increases the potential for cyber intrusion. This means there are several risks specific to Industry 4.0, the most significant being:

- IoT vulnerabilities - smart sensors often run lightweight operating systems with minimal security. Once compromised, they can bridge IT and OT networks.

- Cloud risks - monitoring platforms located in the cloud expose production data to external threats if misconfigured.

- AI and automation - Systems using generative AI can be manipulated through data poisoning or adversarial inputs, leading to flawed decisions or unsafe operations.

- Legacy systems - research shows many SMEs are forced to rely on physical devices and equipment (SCADA, PLCs, and HMIs) running outdated firmware, never designed for internet exposure.

Attackers are typically ransomware groups which are sophisticated and target SMEs with social engineering (phishing) techniques to gain access to admin accounts, expecting quick pay outs to resume operations. Never forget disgruntled employees or contractors with access to OT systems and in some cases competitor and state-sponsored espionage. Service providers supplying automation platforms, or remote diagnostics and support may introduce vulnerabilities.

Digging deeper into the problem for manufacturing and production

According to Trustwave, key OT risks include:

- Poor segmentation - IT and OT networks often share infrastructure, allowing attackers to move laterally.

- Limited patching - OT systems rarely receive updates due to downtime concerns.

- Inadequate monitoring - OT traffic is static and low-volume, making anomalies hard to detect.

- Authentication gaps - legacy systems may transmit credentials in clear text or lack access controls.

- Skills gap - few engineers understand both cybersecurity and OT safety, leading to blind spots.

Generic cyber risks still apply and often go unnoticed phishing and social engineering attacks on core business support functions, to gain access or install malware such as ransomware. Remote exploitation of technical vulnerabilities is also an ongoing threat.

AI is both a tool and a threat and depending on the type of AI and how it's deployed, risks need to be identified and managed. They might include:

- Automated phishing -attackers use AI to craft convincing emails tailored to your business.

- Data poisoning - manipulated inputs can cause flawed decisions in AI-driven systems.

- Deepfake impersonation - voice or video impersonation of executives is emerging as a fraud tactic.

What can you do?

Start with low-cost, high-impact actions

As a minimum:

- Train your staff - train office staff with general cyber awareness training and use sector-specific training for engineers and technicians supporting shop floor equipment.

- Review third-party access - review staff and contractors accessing remotely and disable unless essential.

If you have significant OT and IoT you should:

- Segment your networks - separate OT from IT using VLANs or firewalls.

- Create an OT asset inventory - know what devices you have and what firmware they run.

- Apply available patches - schedule downtime for critical updates.

- Build an incident response plan - include OT-specific recovery steps.

If you have the basics covered and have money to invest you might:

- Deploy passive OT monitoring - use SPAN ports to monitor traffic.

- Implement micro-segmentation - separate production lines and admin systems.

CyberSolver's six solutions — which one is right for you?

While generalised recommendations are great, there is no substitute for focussing on your business, your priorities and your specific risks. The convergence of IT and OT, the rise of Industry 4.0, and the increasing sophistication of attackers mean that industry SMEs must realise that cyber security is no longer just an IT issue and act now.

CyberSolver helps you take practical, affordable steps to protect your operations. Whether you're just starting or ready to invest, we offer six packaged solutions geared up to Manufacturing SMEs:

- Use Risk Reduction when you do not know where to start and receive recommendations based on a comprehensive risk assessment, covering business operations and manufacturing-specific vulnerabilities in OT and IoT. You'll get a prioritised, pragmatic plan of action to mitigate your biggest risk areas.

- Use Compliance when you must meet legislative needs such as GDPR, or DORA, or want to achieve a recognised certification.

- Use Staff Awareness to reduce human risk through manufacturing‑specific training for operational and support staff.

- Use Resilience to run interactive workshops to build your response capability and strengthen technical defences.

- Use vCISO for low-cost executive and board‑level strategy, prioritisation, and reporting as and when you need it.

- Use the CyberSolver Toolkit for templates, playbooks, and repeatable operational artefacts.

Book a short no-obligation chat with CyberSolver to discuss your highest‑impact activities and how we can help.